catalog

YOUR MANAGER

DESCRIPTION

Universal single-stage worm gearbox 6CH-100 is designed to increase the torques and simultaneously reduce the rotational speed. The gearbox is used under operating conditions in accordance with GOST R50891-96:

- the load is steady and varying, unidirectional and reversal;

- the operation is continuous or stick-slip;

- rotation of shafts in any direction;

- the rotational speed of the input shaft should not exceed 1800 rpm;

- the sliding velocity of the gear should not exceed 10 m/s;

- atmosphere types I and II in accordance with GOST 15150-69 when the dust content of air is not more than 10 mg/m3, climatic category are U, T, for placement categories 1-3 and climatic category UKHL for placement category 4 in accordance with GOST 15150-69.

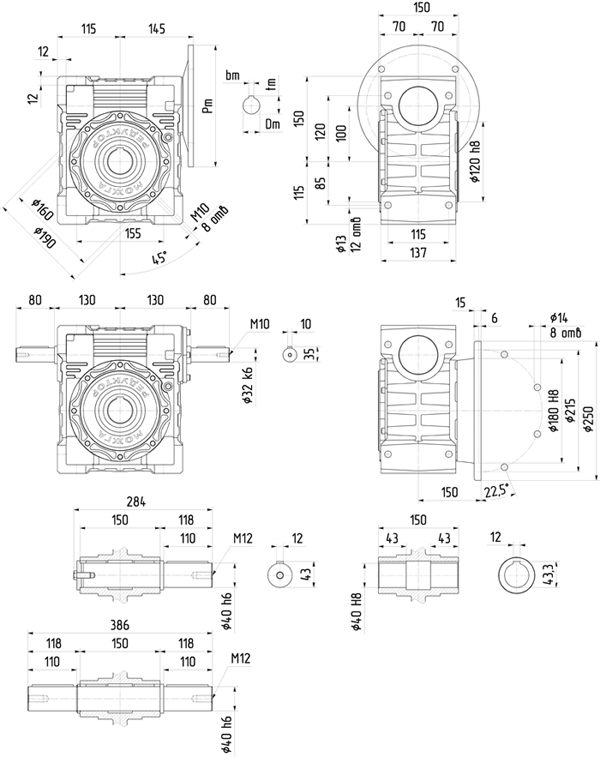

Overall and connection dimensions GEARBOX 6CH-100

Gearbox designation

Example of gearbox designation when ordering and in the documentation of other products where it can be applied: Gearbox 6CH-100-40-51-1-КК-2VUZ, TU 4161-009-68260994-2011, where:

- 6CH — gearbox type — single-stage, worm;

- 100 — center distance;

- 40 — nominal gear ratio;

- 51 — assembling variant in accordance with GOST 20373-94;

- 1 — variant of worm-and-worm gear placing;

- К — design variant of the input shaft;

- К — design variant of the output shaft;

- 2 — accuracy class in accordance with GOST R 50891-96;

- V — with fan;

- UZ — type of climatic category in accordance with GOST 15150-69.

Specifications

Nominal gear ratios (U nom.), torsional capacity (Mt), values of the input rated horsepower (W), as well as the efficiency factors (ζ):

|

Nominal gear ratios U nom. |

Torsional capacity (Мt), design efficiency (ζ), input rated horsepower (W), at rotational speed of the input shaft 1500 rpm. | ||

|

6CH-100 |

|||

|

Мт, Нм |

ζ, % |

W, кВт |

|

|

8.0 |

400 |

0,92 |

8,5 |

|

10.0 |

380 |

0,91 |

6,6 |

|

12.5 |

370 |

0,90 |

5,4 |

|

16.0 |

420 |

0,88 |

4,6 |

|

20.0 |

390 |

0,86 |

3,5 |

|

25.0 |

370 |

0,85 |

2,9 |

|

31.5 |

440 |

0,79 |

2,7 |

|

40.0 |

390 |

0,75 |

2,0 |

|

50.0 |

380 |

0,74 |

1,7 |

|

63.0 |

300 |

0,66 |

1,1 |

|

80.0 |

280 |

0,65 |

0,85 |

The values of efficiency in the first 200 hours of the gearbox operation should be not less than 80% of those specified in the table. In case of the worm-and-worm gear placing according to the variant 2 (worm is above wheel), Mt should be reduced by 20%. During continuous operation, the gearboxes U ≥ 50 should not be applied. Torsional capacity (Mt) and efficiency (ζ) are given under the condition of using the lubricant «Transol-100» TU38 USSR 201 352-84. In case of using formulated oils of the IGP or ASZp series, the values of Mt and ζ are reduced by 7%, in case of using unformulated oils of the «cylinder» and MS series, the should be reduced by 20%.

The allowable cantilever loads in the middle of the shaft ends:

|

Gearbox designation |

Input shaft, N |

Output shaft, N |

| 6CH-100 |

920 |

7280 |

Weight (kg), up to ± 5%:

| Assembling variant | Gearbox Weight, kg |

| Assembling variant 56 |

52 |

Corrected sound power level, dB at nominal transmitted power:

| до 1,5 кВт |

82 дБ |

| от 1,5 до 4 кВт |

85 дБ |

| от 4 до 12 кВт |

89 дБ |

| свыше 12 кВт |

94 дБ |